Wireways versus Auxiliary Gutters

Wireways vs. Auxiliary Gutters: A Technical Comparison Under the 2023 NEC

By Electrical Code Academy, Inc.

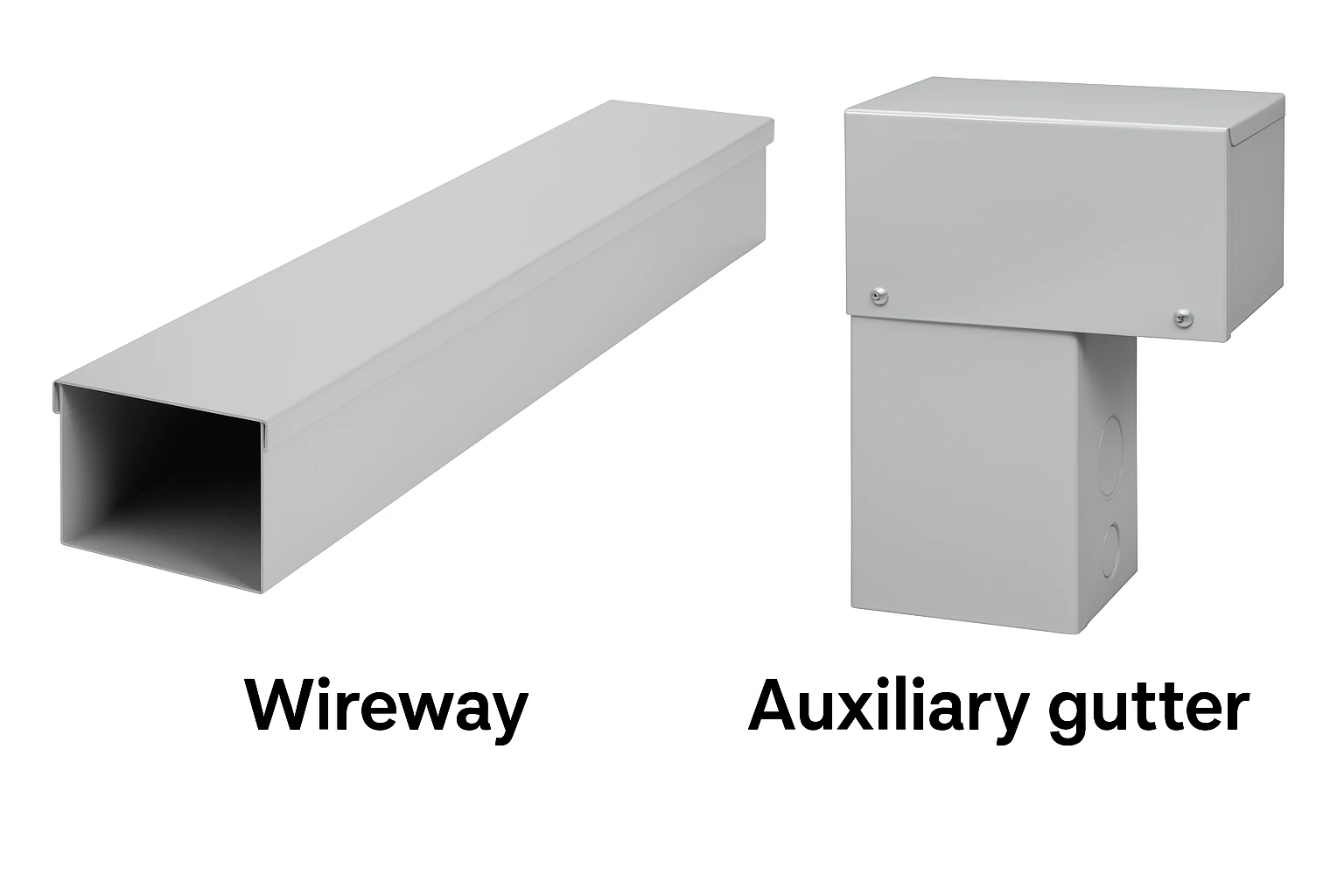

Wireways Defined

A wireway is a raceway constructed with a rectangular cross-section and removable or hinged covers along its length. The design permits accessible routing, pulling, splicing, and tapping of conductors within the enclosure.

- Conductor fill: At any cross-section, total conductor area ≤ 20% of the interior cross-sectional area.

- Ampacity adjustment:

- Metallic wireways: Apply adjustment factors only when >30 current-carrying conductors (CCC) are present at a cross-section.

- Nonmetallic wireways: Apply adjustment factors when >3 CCC are present (the general rule).

- Length: No NEC-imposed maximum length; compliance hinges on fill, ampacity adjustment, support, and listing.

Auxiliary Gutters Defined

An auxiliary gutter is a supplemental wiring space installed adjacent to equipment (e.g., panelboards, switchboards, MCCs). It is not a general-purpose raceway; it relieves congestion at terminations and provides space for conductor bends, taps, and splices.

- Length: Total length limited to 30 ft (applies to metallic and nonmetallic auxiliary gutters).

- Conductor fill: At any cross-section, total conductor area ≤ 20% of the interior cross-sectional area.

- Ampacity adjustment:

- Metallic auxiliary gutters: Apply adjustment factors only when >30 CCC are present at a cross-section.

- Nonmetallic auxiliary gutters: Apply adjustment factors when >3 CCC are present.

Splices, Taps, and Terminations — Required Practices

Both wireways and auxiliary gutters allow splices and taps. The following limits and good-practice items are critical for compliance and performance:

- 75% occupancy at the splice/tap location: At the exact cross-section where splicing/tapping hardware is installed, the combined area of conductors plus splice/tap devices must not exceed 75% of that cross-section.

- 20% conductor fill still applies: Away from splice/tap points, the conductor-only fill cannot exceed 20% at any cross-section.

- Accessibility: Splices/taps must remain accessible by the removable/hinged covers. Do not bury or obstruct access with other equipment or building finishes.

- Listed devices only: Use splicing/tapping means listed and identified for the conductor type, size, and environment (temperature rating, insulation type, and enclosure rating).

- Bend radius and mechanical strain: Provide adequate bending space and strain relief; avoid sharp edges and ensure raceway/entry fittings are listed and properly installed.

- Bonding and continuity: Maintain effective bonding and equipment grounding continuity across all enclosures and fittings; install bonding jumpers where required.

- Conductor organization: Arrange, secure, and label conductors to minimize heat buildup, facilitate inspection, and maintain clear cover closure.

Comparative Analysis

| Feature | Wireway | Auxiliary Gutter |

|---|---|---|

| Primary function | Raceway for routing conductors with accessible covers for pulls, splices, and taps. | Supplemental wiring space directly adjacent to equipment for bends, splices, and taps. |

| Length limitation | No NEC maximum. | 30 ft maximum (metallic and nonmetallic). |

| Conductor fill | ≤ 20% at any cross-section. | ≤ 20% at any cross-section. |

| Splice/tap occupancy (local cross-section) | ≤ 75% (conductors + devices) at splice/tap point; 20% conductor-fill still governs elsewhere. | ≤ 75% (conductors + devices) at splice/tap point; 20% conductor-fill still governs elsewhere. |

| Ampacity adjustment trigger | Metallic: >30 CCC Nonmetallic: >3 CCC | Metallic: >30 CCC Nonmetallic: >3 CCC |

| Typical deployment | Extended horizontal/vertical routing across rooms or equipment lineups. | Short enclosure mounted to the side/top of equipment to relieve termination congestion. |

Code Application Significance

Common violations include: using an auxiliary gutter like a long raceway, exceeding 20% conductor fill, overlooking the 75% splice/tap occupancy at the local cross-section, or misapplying ampacity adjustment triggers—especially on nonmetallic products. Each error increases the risk of excessive heating, poor serviceability, and failed inspections.

Advance Your NEC Knowledge

If you’re ready to lock in these distinctions—20% fill, 75% splice/tap occupancy, metallic vs. nonmetallic derating triggers, and the 30-ft auxiliary gutter limit—the Fast Trax® Program from Electrical Code Academy, Inc. is a comprehensive, industry-proven path to mastery.

CEO and Founder of Electrical Code Academy, Inc. A Virginia Corporation located in Mineral, Virginia